DETAILED DESIGN of a vessel includes determining the proper locations for level gauge/transmitter nozzles.

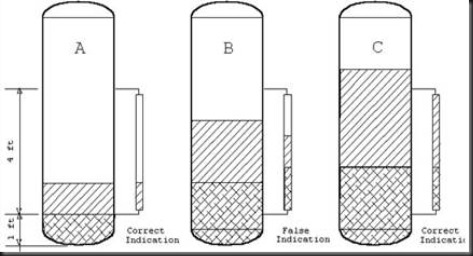

Figure above shows what happens when a gauge glass is connected to a vessel containing a vapour and two liquid phases. Assume that equal amounts of a liquid with Sg = 1.0, e.g. water, and a liquid with Sg = 0.5, perhaps oil, gradually flow into the vessel. Assume further that the span of the gauge glass is four feet, beginning one foot from the bottom of the vessel.

As the level of the oil rises, it flows into the glass. As both liquids rise further, water begins to enter the bottom of the glass. This is the state shown in vessel A. Up to this point, the glass shows a true indication of the level of propane in the vessel. Once water enters the glass, the oil is cut off. A constant plug, one foot thick, floats on top of the water. Its level no longer bears any obvious relationship to the actual level in the vessel. This is state shown in vessel B. The only relationship between the vessel and the glass is that the hydrostatic pressure is the same for both at the point where the glass taps into the vessel. A gauge glass is really nothing more than a manometer.

Once the level of the oil rises above the upper tap, it flows into the glass and the two interface levels adjust to the same elevation, as shown in vessel C. The gauge will continue to read correctly as long as its lower tap is in the water and the upper tap is in propane. If either fluid is withdrawn so that the upper tap is in the vapour space, the glass will once again read falsely.

This same analysis applies to any type of level indication based on density. Remember that a DP transmitter only gives a single reading, i.e. differential pressure. Therefore only a single quantity can be inferred. If the instrument is affected by only two fluids, it can yield the correct interface level between the two. If there are more than two distinct phases within the span of the two taps, it will give a reading based on the average densities of all the fluids within its span.

Capacitance or nuclear level transmitters will give similar results in multiphase situations, based on the average dielectric or nuclear absorption constants, respectively.

Question:

How can the process controls engineer be assured that the level readings are meaningful if even a gauge glass can't be trusted?

- Make the entire vessel out of glass. But, this isn't usually practical.

- Every section of a gauge glass must have separate taps into the vessel so that each pair of taps has no "hidden" phase floating in between. Either that, or accept the fact that until the interface reaches its "normal" range, gauge glasses and transmitters will read falsely.

- For proper location of externally mounted level measurement nozzles, ensure that at least one nozzle is located in the top liquid phase and at least one nozzle is located in the bottom liquid phase.

Reference:

- Chemicalprocessing.com , Best Practices for Level Measurement

This comment has been removed by the author.

ReplyDeleteFirst time I have heard from elisa coating, glass level measurement and absorbance reading was during my time at university. Second time at my first job, and now the third time

ReplyDeleteNice! This blog looks so crispy and informative too...Keep Posting!!

ReplyDeleteLevel Transmitter

We offer different type of telemetry devices which are used in order to track the level of fluids or gases in a particular tank system. Whether you are going to go for monitoring any liquid, the sensor is a mandatory part which is included in all metric devices. This is actually the component which is going to be detecting the level of any chemical and providing you the data. With this in mind, there are quite a few different types of Telemetry Chemical Level Sensor and yet these sensors are among the most popular ones.

ReplyDelete

ReplyDeleteWe are Suppliers and manufacture of Pressure Gauge. kevitits Industrial Technologies LTD is one of the best Pressure Gauge, Level switches suppliers in Dubai. We offer Gauge, Switch, and Radar Level Transmitter at affordable rates in Dubai, UAE. Call us at +971567076530.

temperature gauge manufacturers in UAE