Table below provide a rough guide on selection of fluid package.

However, the guide doesn't provide a detail description in selection of activity coefficient.

Source: Elliot, Liraj : Prentiice Hall , 1999

A blog dedicated for knowledge sharing of process design and process modelling

Table below provide a rough guide on selection of fluid package.

However, the guide doesn't provide a detail description in selection of activity coefficient.

Source: Elliot, Liraj : Prentiice Hall , 1999

Generally, pig detector is group by intrusive and non-intrusive type. For non-intrusive type pig, there is no mechanical part that required to be installed inside the pipeline.

Henceforth, it has a number of benefits:

1. Any type of PIG can be detected in both directions.

2. There are no mechanical moving parts resulting in low maintenance.

3. Non-intrusive design benefits include:

- No wetted parts

- No pipe pressure drop

- Easy to install (no tappings or welding required)

- No shutdown required for installation

4. Finally, it is easy to retrofit for existing installations with no need for modifications to the piping or PIG

The non-intrusive pig detector is an acoustic device. When a PIG travels through the pipe, the friction between the PIG and the pipe will generates a characteristic noise. This noise contains information that can be interpreted to gain more knowledge on the situation inside the pipe. The noise is detected and can be transformed into digital signal.

Image courtesy from Roxar Pig Detector catalogue. Emerson Process Management.

A strange condition where the Equilibrium Unit Operation Extension fail to generate neither Txy plot nor xy plot.

The Plot and update plot tab seems unresponsive.

Your Comment is highly appreciated.

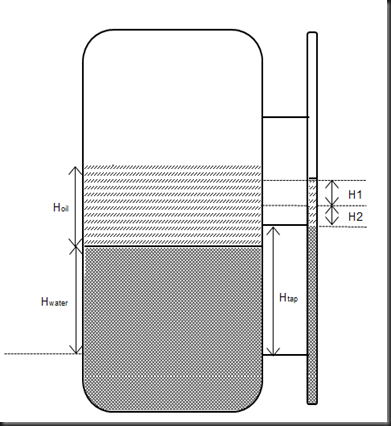

DETAILED DESIGN of a vessel includes determining the proper locations for level gauge/transmitter nozzles.

Figure above shows what happens when a gauge glass is connected to a vessel containing a vapour and two liquid phases. Assume that equal amounts of a liquid with Sg = 1.0, e.g. water, and a liquid with Sg = 0.5, perhaps oil, gradually flow into the vessel. Assume further that the span of the gauge glass is four feet, beginning one foot from the bottom of the vessel.

As the level of the oil rises, it flows into the glass. As both liquids rise further, water begins to enter the bottom of the glass. This is the state shown in vessel A. Up to this point, the glass shows a true indication of the level of propane in the vessel. Once water enters the glass, the oil is cut off. A constant plug, one foot thick, floats on top of the water. Its level no longer bears any obvious relationship to the actual level in the vessel. This is state shown in vessel B. The only relationship between the vessel and the glass is that the hydrostatic pressure is the same for both at the point where the glass taps into the vessel. A gauge glass is really nothing more than a manometer.

Once the level of the oil rises above the upper tap, it flows into the glass and the two interface levels adjust to the same elevation, as shown in vessel C. The gauge will continue to read correctly as long as its lower tap is in the water and the upper tap is in propane. If either fluid is withdrawn so that the upper tap is in the vapour space, the glass will once again read falsely.

This same analysis applies to any type of level indication based on density. Remember that a DP transmitter only gives a single reading, i.e. differential pressure. Therefore only a single quantity can be inferred. If the instrument is affected by only two fluids, it can yield the correct interface level between the two. If there are more than two distinct phases within the span of the two taps, it will give a reading based on the average densities of all the fluids within its span.

Capacitance or nuclear level transmitters will give similar results in multiphase situations, based on the average dielectric or nuclear absorption constants, respectively.

Question:

How can the process controls engineer be assured that the level readings are meaningful if even a gauge glass can't be trusted?

Reference: